Some projects begin with months of planning—this one started with a $40 stroke of luck at my local recycling center. Buried between a stack of discarded DVD players and a stereo receiver with half the knobs missing was a Pioneer PL-550, dusty but unmistakably intact. I plugged it in, half expecting smoke, but incredibly, it spun up smoothly. The motor was quiet, the tonearm drifted gracefully, and even the strobe worked. Only one thing really held it back from greatness: the faux-wood vinyl veneer was absolutely trashed.

That was all the invitation I needed.

Assessing the Rescue Candidate

Up close, the PL-550 was a time capsule—heavy, overbuilt, and unapologetically analog. Pioneer built these decks like tanks, but the original vinyl veneer doesn't age nearly as well as the mechanics. Mine was bubbling, peeling at every corner, and faded into that special shade of “sunburnt particleboard.”

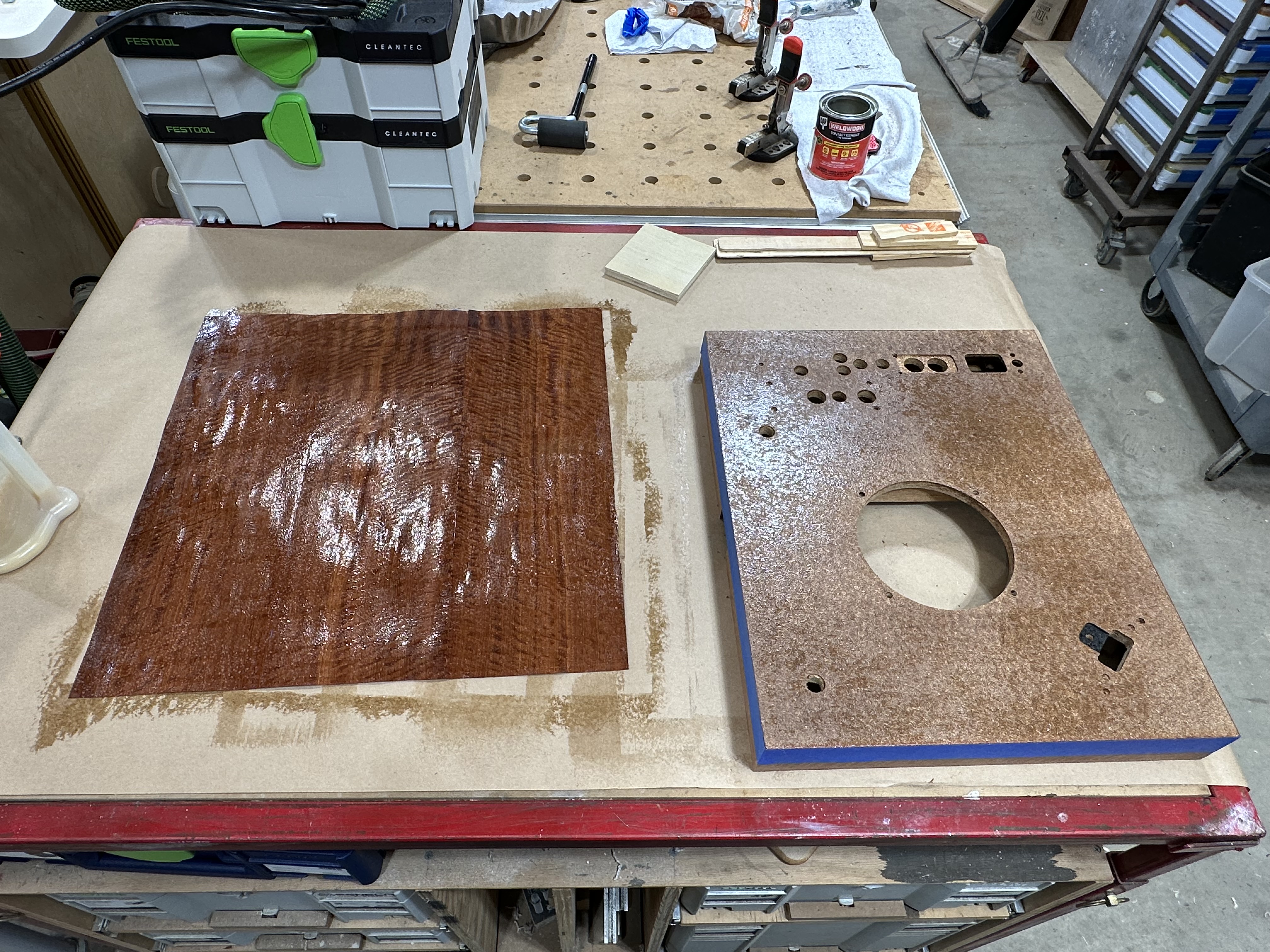

The faux veneer came off almost too easily—heat gun, putty knife, and patience. Once the adhesive softened, the vinyl peeled away in long, brittle sheets. Underneath was the raw MDF plinth, surprisingly clean and flat. I took my time around the edges and corners, especially near the original labels, which I wanted to preserve.

Mechanically? Nearly perfect. Cosmetically? A disaster.

The plan became obvious: strip the old veneer, replace it with real hardwood, give the deck a second life.

Choosing and Applying the New Veneer: Sapele

I wanted something that honored the turntable’s vintage vibe while elevating it. Sapele was the perfect choice—deep reddish tones, subtle shimmer, and a grain pattern that catches light beautifully.

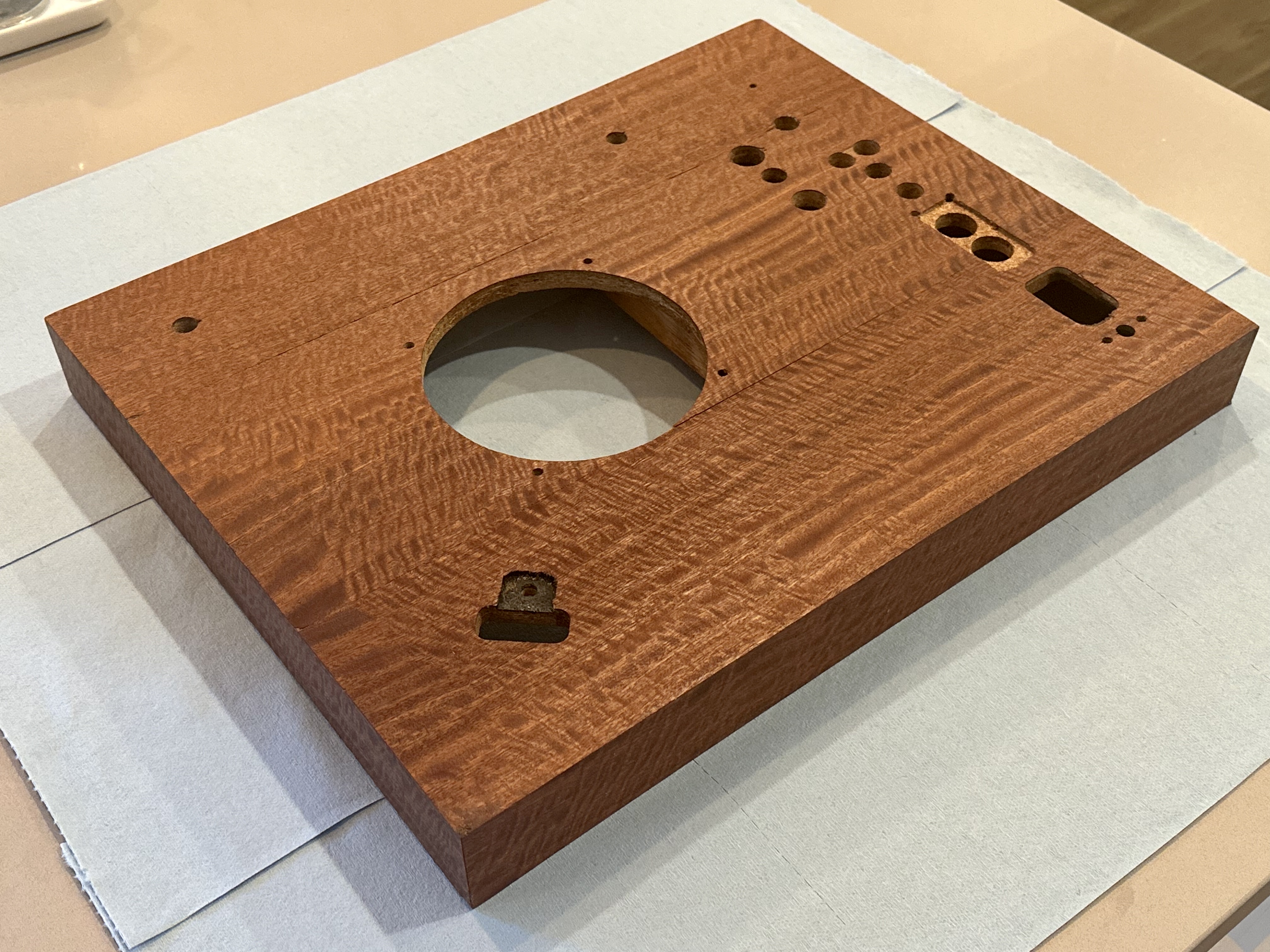

Working with veneer is equal parts craft and meditation. I cut each panel oversized, aligned the grain to flow naturally around the plinth, and bonded it using heat-activated veneer glue. After trimming the edges flush with a sharp blade, I finished the surface with several coats of satin polyurethane.

The result was transformative: the PL-550 suddenly looked like a piece of high-end furniture rather than a relic rescued from the scrap heap.

Saving the Original Labels

One of the details I’m proudest of is preserving the original Pioneer control labels—the speed markings, the cueing indicators, the strobe adjustments. They give the deck its identity, and losing them would have made the restoration feel incomplete.

I carefully removed each label, cleaned away decades of glue residue, and reinstalled them onto the new sapele surface. Against real hardwood, those vintage labels pop in a way they never did on fake veneer.

It’s a small detail that makes the whole deck feel authentic.

A New Cartridge for a New Life: Ortofon 2M Blue

To complete the resurrection, I swapped out the aging cartridge for an Ortofon 2M Blue—a perfect match for a deck of this pedigree. Installation was straightforward, and once properly aligned, the sound was everything I hoped for:

- Clean, detailed highs

- Tight, articulate bass

- A wide, open soundstage

Hearing the first record on the fully restored PL-550 was a moment of pure satisfaction. The table wasn’t just functioning—it was performing.

Final Results & Reflections

By the end of the project, the $40 recycling-center gamble had turned into a showpiece turntable—one that looks better than it did new, yet maintains all its original character. The sapele veneer brings warmth and sophistication, the labels preserve its heritage, and the 2M Blue elevates its sonic performance.

This restoration reminded me why I love reviving old gear: it’s not just about saving money or rescuing something from the landfill. It’s about giving a classic piece of engineering the chance to keep doing what it was built to do—and to look great doing it.